Choose a standard size as568 o ring using this o ring size chart.

O ring groove design guide.

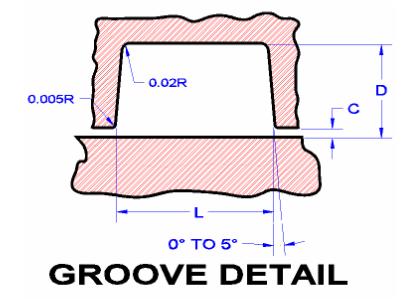

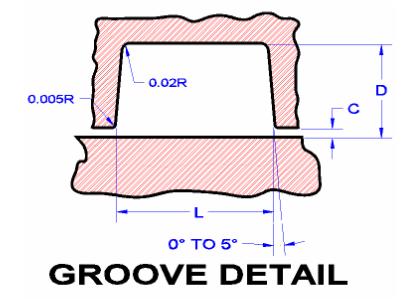

Designing the parts of an application where o rings will be applied is broadly termed o ring groove design.

Machining specifications the gland fill is the percentage of the gland that is occupied by the o ring.

Here you will find an o ring groove design guide to help you with your o ring gland dimensions.

Contact seal design for more information or download our metric sizing guide today.

These are intended for use in basic design consideration and to understand the core principles involved in o ring gland groove design.

It is calculated by dividing the cross sectional area.

Find the right o ring groove design and easily order your o ring online from the worldâ s largest inventory network.

Groove fill of the installed o ring should not be more than 85 to allow for possible o ring thermal expansion volume swell com.

Learn more about metric o ring groove designs and dimensions here.

Otherwise contact us and we can custom mold any size or shape o ring you need.

Through our extensive research we believe that these o ring groove dimensions and fit details will provide the optimum o ring compression squeeze for your seal to prevent o ring leaks.

The best o rings are useless without the right groove design which becomes increasingly important the more demanding the application environment.

716 759 3344 canada hq.

O ring groove design considerations and engineering guides for static face seals metric o rings static dovetail o rings static rod piston o rings and dynamic rod piston o rings.

Metric o ring groove designs vary greatly and choosing the right one for your application is important for maximum o ring performance.

Global o ring and seal has developed o ring groove design and gland dimension guidelines.

O ring groove design overview.

This metric o ring groove design reference guide will help you find the right radius back up pressure and other o ring dimensions for basic applications.

Design and dimension the groove that your o ring will go into by researching our o ring groove design guide.

In order to seal properly the o ring has to deform in the application by being compressed and stretched in any number of ways.

Review the general o ring groove design considerations before moving onto the.